13

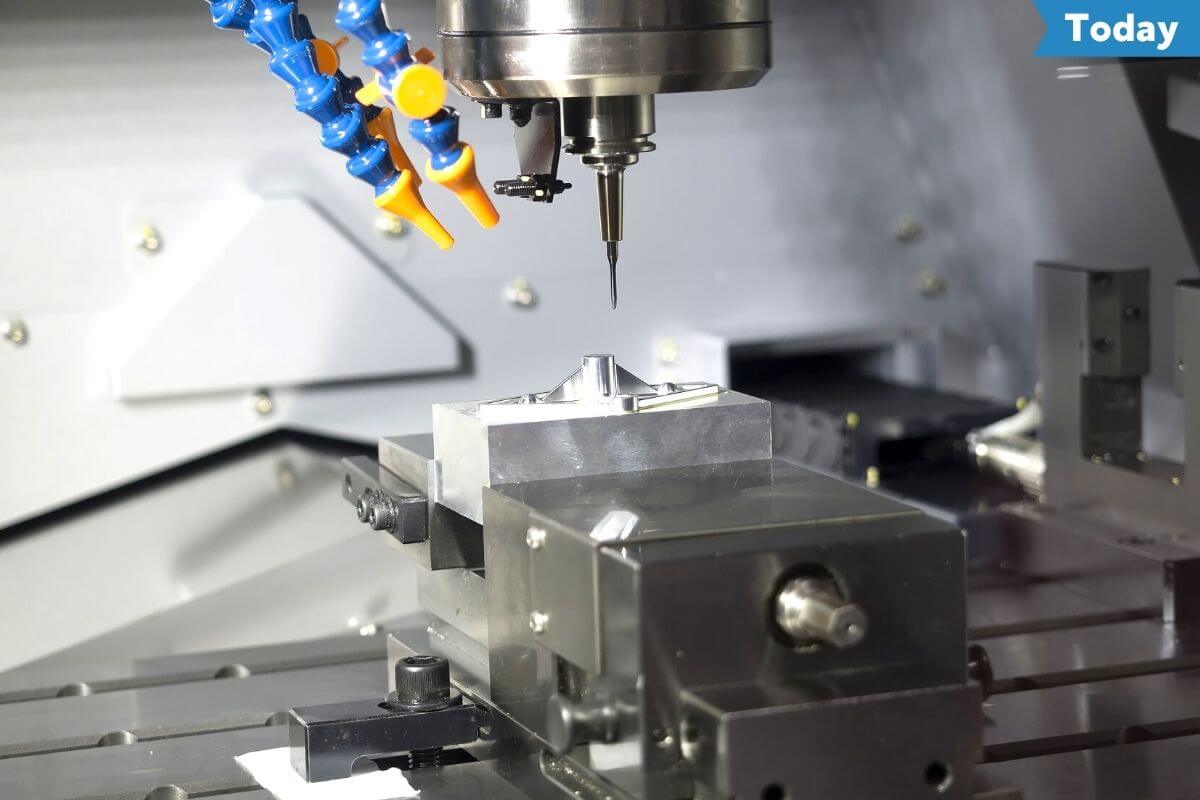

Introduction to CNC Machine Tool Accessories and Components

CNC machines rely on a wide array of accessories and components to ensure precision, efficiency, and versatility in manufacturing processes. From tooling systems to coolant management solutions, each accessory plays a critical role in optimizing machine performance, extending tool life, and achieving high-quality part production. This guide provides an in-depth look at essential CNC machine accessories and components, categorized by function and application.

1. Tooling Systems and Holders

Tooling is the backbone of CNC machining, and selecting the right accessories ensures compatibility, rigidity, and accuracy.

A. Tool Holders

- Collet Chucks: Versatile and cost-effective, ER collet chucks secure tools with diameters ranging from 1mm to 32mm, ideal for prototyping and general-purpose machining.

- Hydraulic Tool Holders: Offer ultra-low runout (≤1µm) by using hydraulic pressure to clamp tools, making them perfect for high-precision finishing operations.

- Shrink-Fit Holders: Provide exceptional rigidity and balance by heating the holder to expand the bore, then cooling it to shrink around the tool shank (≤0.5µm runout).

- Side-Lock (End Mill Holders): Robust and simple, these holders use a single set screw to secure tools, suitable for heavy-duty roughing and interrupted cuts.

- Mill-Chuck (Power Clamping Chucks): Designed for large-diameter tools (≥16mm), they distribute clamping force evenly across multiple jaws, reducing vibration during high-torque applications.

B. Cutting Tools

- End Mills: Available in square, ball-nose, and corner-radius designs for contouring, slotting, and profiling.

- Drills: High-speed steel (HSS) or carbide drills for precise hole-making in metals, plastics, and composites.

- Reamers: Used to finish holes to tight tolerances with superior surface quality.

- Taps and Dies: For internal and external threading operations.

- Insert Tools: Replaceable carbide inserts reduce tooling costs and downtime in high-volume production.

2. Workholding Solutions

Securely holding workpieces is essential for maintaining accuracy and safety during machining.

A. Vises

- Mechanical Vises: Manual or powered clamping for general-purpose machining.

- Hydraulic Vises: Offer consistent clamping force and quick operation, ideal for automation.

- Modular Vises: Allow for multiple setups on a single fixture, increasing flexibility.

B. Fixtures and Jigs

- Custom Fixtures: Tailored to specific part geometries for repeatable positioning.

- Tombstones: Multi-sided fixtures for high-volume production, enabling simultaneous machining of multiple parts.

- Zero-Point Clamping Systems: Quick-change platforms that minimize setup time and ensure precise alignment.

C. Chuck Systems

- 3-Jaw Chucks: Common for round workpieces, offering balanced clamping.

- 4-Jaw Independent Chucks: Allow for precise adjustment of each jaw, suitable for irregular shapes.

- Collet Chucks: For cylindrical parts, providing high accuracy and repeatability.

3. Coolant and Lubrication Systems

Effective coolant delivery improves tool life, surface finish, and chip evacuation.

A. Coolant Nozzles and Sprayers

- Adjustable Nozzles: Direct coolant precisely to the cutting zone to reduce heat buildup.

- High-Pressure Coolant Systems: Deliver coolant at pressures up to 1,000 PSI for deep-hole drilling and high-speed machining.

B. Coolant Tanks and Pumps

- Reservoirs: Store coolant and filter out chips and debris.

- Centrifugal Pumps: Circulate coolant efficiently through the system.

C. Mist Collectors

- Filter airborne coolant mist to maintain a clean working environment and comply with safety regulations.

4. Automation and Accessories

Enhance productivity and reduce manual intervention with these automation tools.

A. Automatic Tool Changers (ATC)

- Carousel or chain-type ATCs enable rapid tool changes, reducing idle time in multi-tool operations.

B. Pallet Changers

- Allow for continuous machining by swapping loaded pallets in and out of the workzone.

C. Probing Systems

- Touch Probes: Measure part dimensions and tool offsets automatically, ensuring accuracy.

- Laser Probes: Non-contact measurement for delicate or high-precision components.

D. Bar Feeders

- Automatically feed bar stock into a lathe for unattended production of long parts.

5. Spindle and Drive Components

Critical for machine performance, these components ensure smooth operation and high-speed capabilities.

A. Spindle Units

- Built-in Spindles: Integrated into the machine head for compact designs.

- Motorized Spindles: High-speed options (up to 60,000 RPM) for precision machining.

B. Bearings and Seals

- High-precision bearings reduce vibration and wear, while seals prevent contamination.

C. Drive Belts and Pulleys

- Ensure efficient power transmission from the motor to the spindle.

6. Safety and Monitoring Accessories

Protect operators and equipment while optimizing performance.

A. Enclosures and Guards

- Full or partial enclosures contain chips and coolant splashes, improving safety and cleanliness.

B. Emergency Stop Systems

- Redundant stop buttons and brake systems halt machine operation instantly in case of emergencies.

C. Machine Monitoring Software

- Track spindle load, tool wear, and vibration in real time to prevent downtime.

7. Maintenance and Calibration Tools

Prolong machine life and maintain accuracy with these essential tools.

A. Laser Calibration Systems

- Measure and correct geometric errors in machine axes for sub-micron accuracy.

B. Leveling Pads and Feet

- Ensure the machine is perfectly level to prevent vibrations and alignment issues.

C. Cleaning Kits

- Brushes, solvents, and lubricants for routine maintenance of tool holders, spindles, and guides.

Conclusion

CNC machine accessories and components are diverse, each serving a specific purpose to enhance productivity, precision, and safety. From advanced tooling systems like hydraulic and shrink-fit holders to automation solutions like ATCs and pallet changers, investing in the right accessories ensures your CNC machine operates at peak efficiency. Regular maintenance using calibration tools and safety accessories further extends machine life and reduces operational costs. By understanding the functions and benefits of each component, manufacturers can optimize their CNC setups for a wide range of applications, from aerospace to automotive and beyond.

Comments (3)

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam viverra euismod odio, gravida pellentesque urna varius vitae, gravida pellentesque urna varius vitae. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam viverra euismod odio, gravida pellentesque urna varius vitae. Sed dui lorem, adipiscing in adipiscing et, interdum nec metus. Mauris ultricies, justo eu convallis placerat, felis enim ornare nisi, vitae mattis nulla ante id dui.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam viverra euismod odio, gravida pellentesque urna varius vitae, gravida pellentesque urna varius vitae.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam viverra euismod odio, gravida pellentesque urna varius vitae, gravida pellentesque urna varius vitae.