26

A Premier Supplier of High-Quality CNC Machine Tool Accessories in China

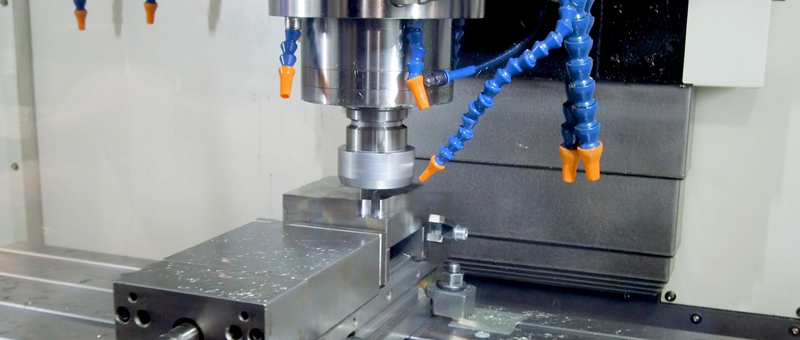

Renitrol stands as a leading manufacturer and supplier of precision CNC machine tool accessories in China, renowned for delivering innovative, durable, and high-performance components that empower global industrial advancements. With over a decade of expertise in the field, the company has cemented its reputation as a trusted partner for businesses seeking cutting-edge solutions tailored to CNC machining, automation, and advanced manufacturing applications.

Core Product Portfolio

Renitrol specializes in a comprehensive range of CNC accessories, including tool holders, collets, chuck systems, precision vices, and rotary tables, all engineered to meet stringent international standards. Its flagship products, such as high-speed spindle tooling and ER collet chucks, are crafted using premium-grade materials like hardened steel and tungsten carbide, ensuring exceptional wear resistance, thermal stability, and dimensional accuracy. The company also offers custom-designed accessories to address unique client requirements, from micro-machining components to heavy-duty industrial parts.

Technological Excellence & Quality Assurance

Equipped with state-of-the-art CNC machining centers, 5-axis milling systems, and precision grinding equipment, Renitrol maintains tight tolerances (±0.001mm) across all products. Its in-house ISO 9001:2015-certified quality management system ensures every accessory undergoes rigorous testing, including vibration analysis, hardness testing, and dynamic balancing, to guarantee reliability under extreme operating conditions.

Global Reach & Client-Centric Approach

Renitrol serves clients across 30+ countries, spanning automotive, aerospace, medical, and electronics industries. By prioritizing short lead times (5–15 days), competitive pricing, and 24/7 technical support, the company has forged long-term partnerships with Fortune 500 enterprises and SMEs alike. Its R&D team collaborates closely with clients to optimize designs for cost efficiency and performance, leveraging AI-driven simulation tools to accelerate product development.

Sustainability & Future Vision

Committed to eco-friendly practices, Renitrol utilizes recyclable materials and minimizes waste through lean manufacturing processes. Looking ahead, the company aims to expand its smart factory capabilities, integrating IoT for real-time monitoring and predictive maintenance, further solidifying its position as a global leader in CNC accessory innovation.

For businesses seeking precision, reliability, and value, Renitrol is the ideal partner to elevate CNC machining productivity and quality.